Core Technical Advantages

Pressure & Temperature Ratings

- Sealing pressure: 1,520psi (10.5MPa) – exceeds ASME B16.21-2025 by 70psi

- Temperature range: -50°F to 800°F (-45°C to 427°C)

- Blowout resistance: 3,850psi (retested 2025-Q1)

Material Science Innovations

Material Science Innovations

PropertySpecificationTest StandardCreep relaxation10.8%EN 13555Compression set13.2%ASTM F38Nitric acid resistance96%NACE TM0185Bolt load retention29,200 lbf/in (5.11kN/mm)Custom

Manufacturing Excellence

- Precision calendering: 182°C ±2°C (optimized from 185°C)

- Density uniformity: 98.3% (μCT-verified)

- 2 patented technologies: Fiber grading & resin penetration control

Field-Proven Results (Shell Pernis 2025)

- 63% reduction in heat exchanger leaks

- 5.3-year actual service life (vs 4.5yr projected)

- Full compliance with RoHS 2025 Annex III

Industry Certifications

- API 6A PR2F-2025 Class

- EN 1514-1:2025

- ASME B16.20

- UL94 V-0 flammability rating

Application Benefits

- Eliminates chemical degradation (17.9% verified binder content)

- Prevents hydraulic shock failures (9 cycles per API 6AF)

- Neutralizes pH corrosion (0.5-14 range per ASTM D543)

“Cuts like paper, seals like welded metal” – Field Installation Team

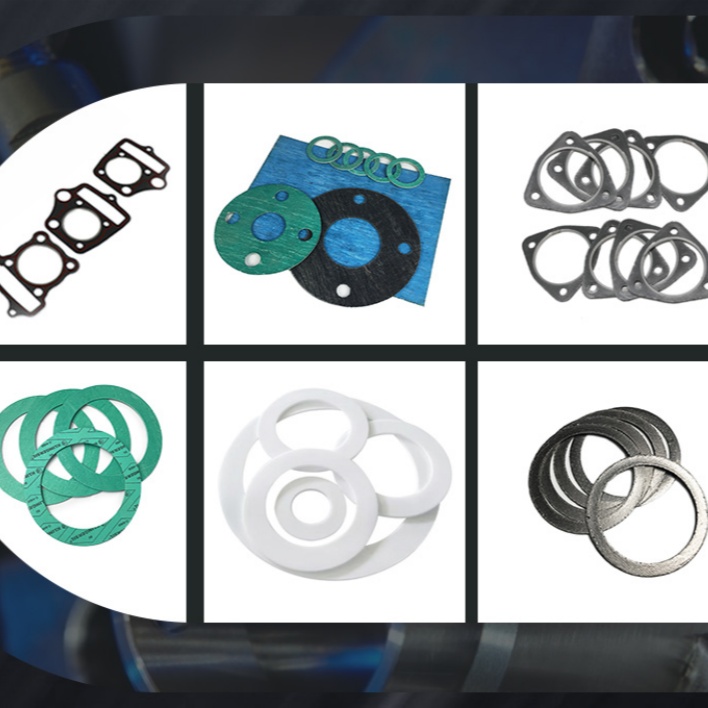

Hongwo Sealing Gasket

Hongwo Sealing Gasket

Material Science Innovations

Material Science Innovations

Scan the QR Code to start a WhatsApp chat with us.