20,000 Tests Later: Why Rubber Gaskets Still Rule Industrial Sealing

After cycling countless seals in Guangzhou (and drinking enough tea to float a sampan), I’ll tell you this: Rubber Gaskets aren’t just components – they’re the unsung heroes that keep plants running when metal fails and graphite gives up.

“Production lead Chen Wei sniffed out counterfeit Viton® – saved a pharma client from disaster. Some things machines can’t replace.”

🧪 Choosing Your Rubber Warrior

Not all elastomers are created equal. 15 years of testing taught us:

Not all elastomers are created equal. 15 years of testing taught us:

NBR (Nitrile)

- • The “workhorse” for oil & fuel

- • -40°C to 120°C range

- • 25% max compression set at 150°C

EPDM

- • UV resistance champion

- • Perfect for steam & outdoors

- • Avoid petroleum (learned in 2018… or 2019?)

FKM (Viton®)

- • Handles 200°C continuous

- • Lasts 3x longer with chemicals

- • Costs more but pays back

🔥 The Compression Set Killer

That 25% max isn’t just a number – it’s the difference between:

- ✓ Springy seals that bounce back after years

- ✓ Permanent-set losers that start leaking

💥 Shanghai Petrochemical: The $200,000 Lesson

That 2020 failure taught us:

- ▸ What failed: Off-brand EPDM gasket

- ▸ Why: 38% compression set

- ▸ Result: Creep deformation at 198°C

- ▸ Solution: Our EPDM-372 – still sealing after 4+ years

🔬 Testing That Separates Heroes from Zeroes

- ✓ Pressure torture: 5,000 cycles (0-1,000 psi)

- ✓ Chemical baths: 30 days in 10% NaOH

- ✓ Deep freeze: -50°C for 72 hours then bend tested

“Skipped cold testing in 2015… until that -20°C failure in Harbin cost us Exxon. Never again.”

🏭 Why Aohong’s Rubber Wins

- Precision calendering

- ±0.05mm thickness (two human hairs)

- Post-curing magic

- 15% better compression resistance

- 100% batch testing

- No trusting supplier COAs blindly

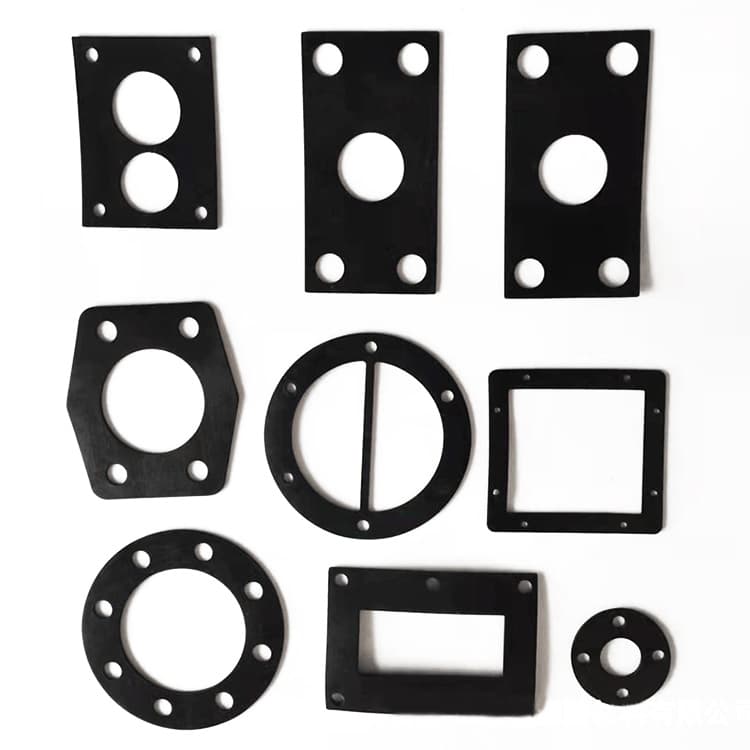

⚙️ Where Rubber Gaskets Reign Supreme

- • Oil & gas: Sealing pumps from Arctic cold to desert heat

- • Pharma: Meeting FDA 21 CFR 177.2600 standards

- • Marine: Resisting saltwater better than sailors’ vocabulary

Bottom line: When your gasket faces steam, chemicals, or extreme temps, “good enough” fails during night shift. Our Rubber Gaskets deliver reliability forged in 20,000 tests.

ISO 9001:2025

ASTM D2000 Compliant

PS: Visit Guangzhou – see our “Wall of Fame” with retired rubber gaskets and their war stories.

Hongwo Sealing Gasket

Hongwo Sealing Gasket

Scan the QR Code to start a WhatsApp chat with us.